sustainably produced.

Through the world-leading, hyper-efficient Smart SX Technology we deliver ultra high purity aluminium products to leading technology companies that are changing the world. Produced in Australia and distributed globally, our range of ultra high purity products are driving the technological advancement of energy storage, solid-state lighting and synthetic sapphire—with enviable green credentials.

Powder & Tablets

Boehmite

Nitrate

Sulfate

Alumina

Our range of purity products are making safer, more efficient and longer lasting Lithuim-ion batteries, LED lighting and Synthetic Sapphire for Smartphones and other devices. And the applications for HPA are growing.

HPA is a key component in Lithium-ion batteries, improving their performance, reliability and safety. HPA coated separators allow for safer, thermally stable batteries. With HPA purity critical for safe, long life batteries, HPA are a key enabler of the e-mobility and energy storage revolution. One of the most exciting uses of Lithium-ion batteries is in battery electric vehicles—the electric vehicle revolution is one of the key drivers for HPA demand globally.

-

AnodeNegatively charged electrode contact

-

HPA SeparatorHPA coated separator providing exceptional heat dissipation and electrical insulation between the anode and cathode, allowing the lithium ions to move between charging and discharging cycles.

-

CathodeA positively charged electrode contact

Synthetic Sapphire is used in scratch resistant glass for premium optics, on premium wristwatch faces , Smartphone camera lenses and LED substrates. HPA is the critical, primary ingredient for synthetic sapphire, sought after for its extreme hardness, its ability to transmit in UV, visible and infrared wavelengths, and for its high heat resistance and thermal conductivity. As in the battery sector, HPA is in demand for its chemical inertness and high electrical resistance. In the production of synthetic sapphire, there is no substitute for HPA.

-

Lenses & GlassHigh end photographic lenses and scratch resistant glass screen protectors are produced from synthetic sapphire

-

Camera LightsSynthetic sapphire is used in the production of optical lenses for photography, including Smartphone cameras

-

Watch FaceLuxury Swiss wristwatches and Smartwatches are made using synthetic sapphire for the face

High purity alumina is critical to the production of LED lighting systems. Synthetic sapphire wafer substrates made from HPA are an essential component of LED lights and relied upon for its ultra-pure surface and exceptional thermal conductivity.

Alpha’s Ultra HPA and its Ultra 5N precursors are also key ingredients for the synthesis of LED aluminate phosphors, critical to the down conversion of light to the visible spectrum.

Demand for this greener system of lighting is projected to increase, and demand for HPA is set to follow the same trajectory.

-

Aluminate PhosphorsUsed to down convert blue light to white light

-

GA-N Circuit & Active LayersSemiconductor materials as active layers of light emitting diodes

-

Synthetic Sapphire SubstrateThe smooth surface on which the LED is built, offering exceptional thermal conductivity to dissipate heat.

In the world of metals, solvent extraction is not new. However solvent extraction has never been successfully applied to aluminium—until now.

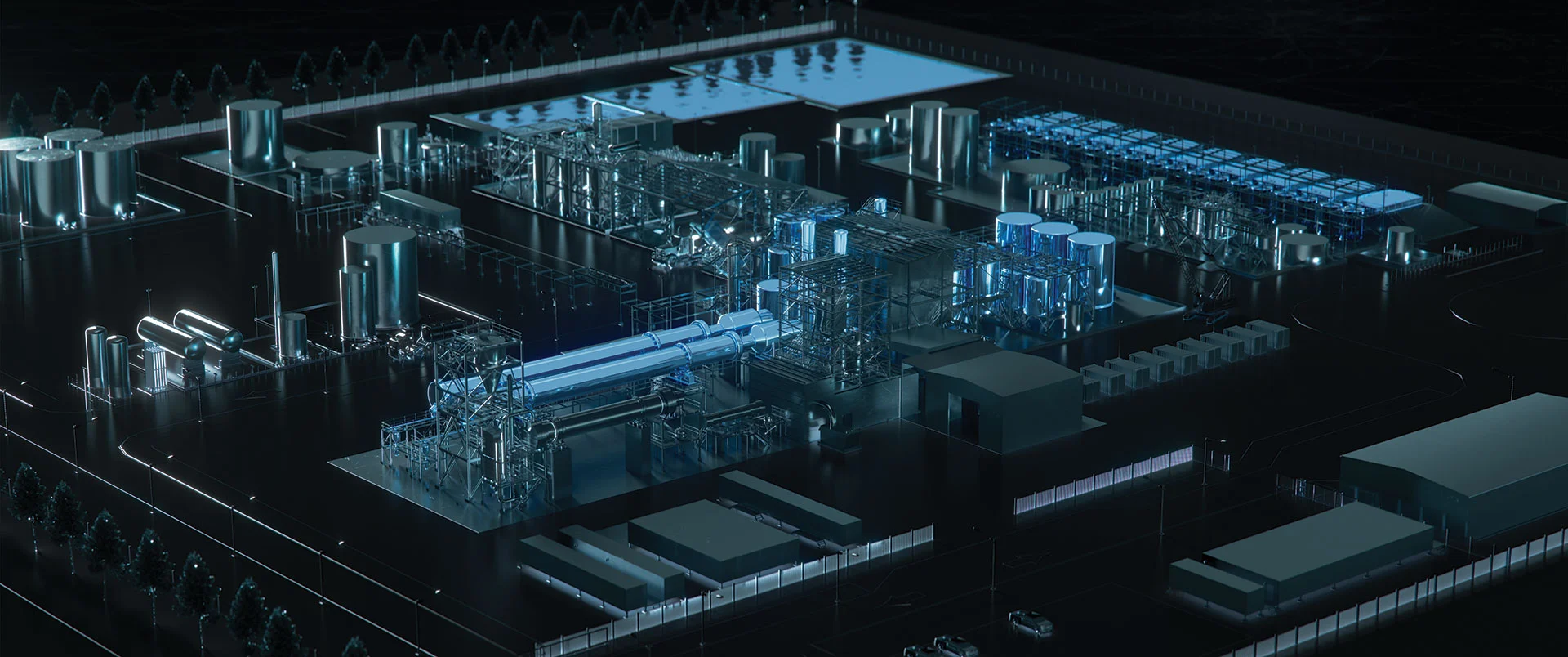

The unique Smart SX Technology is a highly selective scientific process, extracting aluminium with pinpoint accuracy. It gives us the flexibility to generate our ultra high purity aluminium products at a very low carbon footprint.

Smart SX Technology is low impact, in that it recycles its reagents into a saleable by-product, on a 100% basis. While this translates into a cost advantage, the bigger story is the green credentials earned through ingenuity. From here in Australia, we can deliver the world’s most sustainable HPA, aluminium precursors and boehmite to the global markets driving decarbonisation. That’s something we’re proud of.

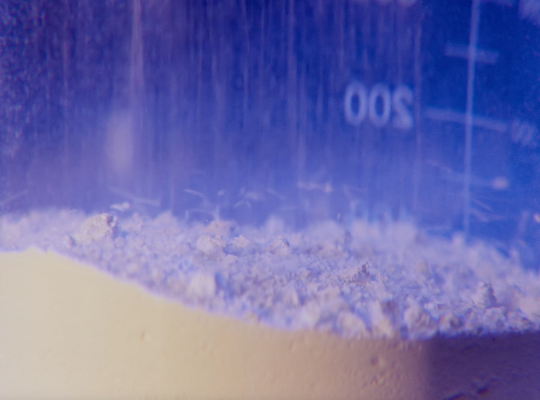

In its purest form (>99.9% purity), aluminium oxide (Al2O3) is known as high purity alumina—or HPA. The high value of this product is derived from its physical properties: excellent thermal conductivity, extreme hardness combined with chemical stability. These features make HPA a critical ingredient in the manufacture of Lithium-ion Batteries, LED lights, scratch-resistant sapphire glass, smartphone components and semiconductor wafers in electronics. Beyond its immeasurable applications, our Ultra HPA Products are made from the most sustainable high purity alumina process technology in the world.

The standing methods for producing HPA lean on old technology. Under existing processes, HPA production is synthesised from aluminium metal feedstock, or produced from hydrochloric acid leach of kaolin clay. Both of these processes are energy intensive, produce high emissions, and create a significant amount of waste. Not only is this detrimental to the environment, it’s inefficient.

Gladstone will be the home of our HPA First facility—a city with a strong industrial pedigree and one of the busiest multi-commodity ports in Australia. This will be the global hub from which we commercialise the Smart SX Technology, with a forecast delivery of 10,000 tonnes of HPA equivalent per annum, creating new opportunities for the local community.

Our unique solvent extraction process has pin point like precision which enables us to deliver ultra high purity aluminium products.